Shut-off and discharge elements

Different discharge elements depending on requirements

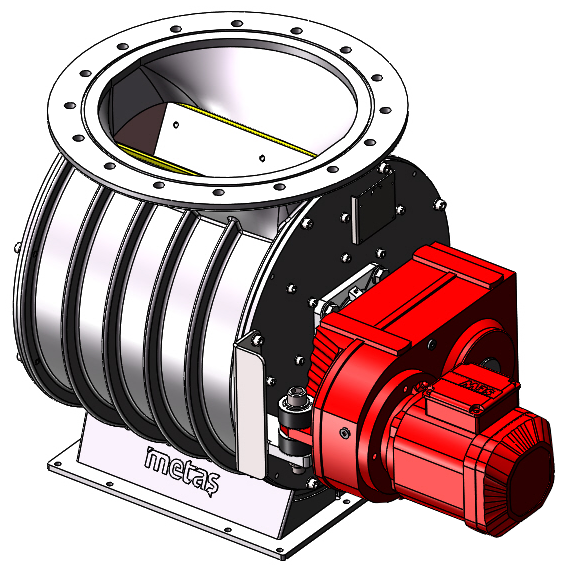

Rotary valve

The bulk material (metal chips) is discharged via the rotary valve. At the same time, the vacuum is maintained in the system by the airtight rotary valve (up to 700 mbar), so that bulk material can be discharged continuously.

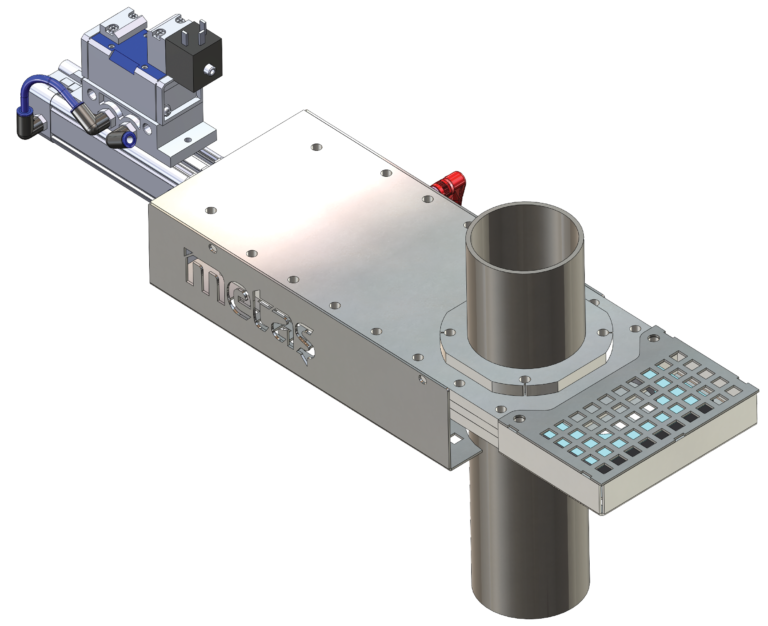

Discharge pusher

Bulk material slide valve, suitable for discontinuous discharge of free-flowing material during metal chip disposal.

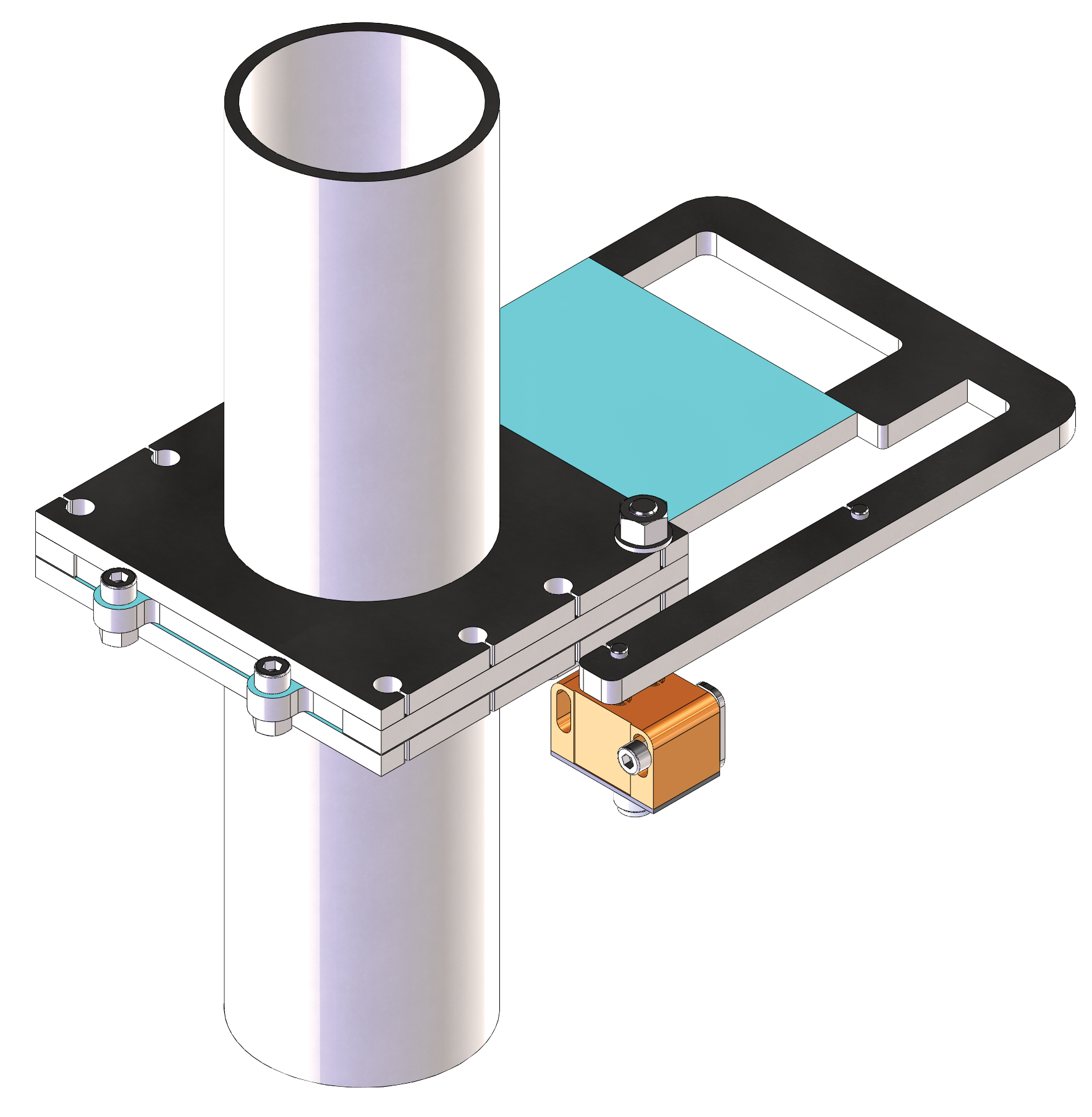

Shut-off unit

Shut-off unit, design as flat seal gate valve

incl. pneumatic cylinder, 5/2-way valve.

Manual slide valve

Optional additional slide valve for maintenance work on extraction systems.

Automatic shut-off unit

The shut-off unit is used to switch the extraction stations on or off, thus controlling the extraction downstream of the crusher.

Rotary distributor

The rotary distributor is used to fill the bulk material evenly into up to two containers.