Metas - Conveyor systems

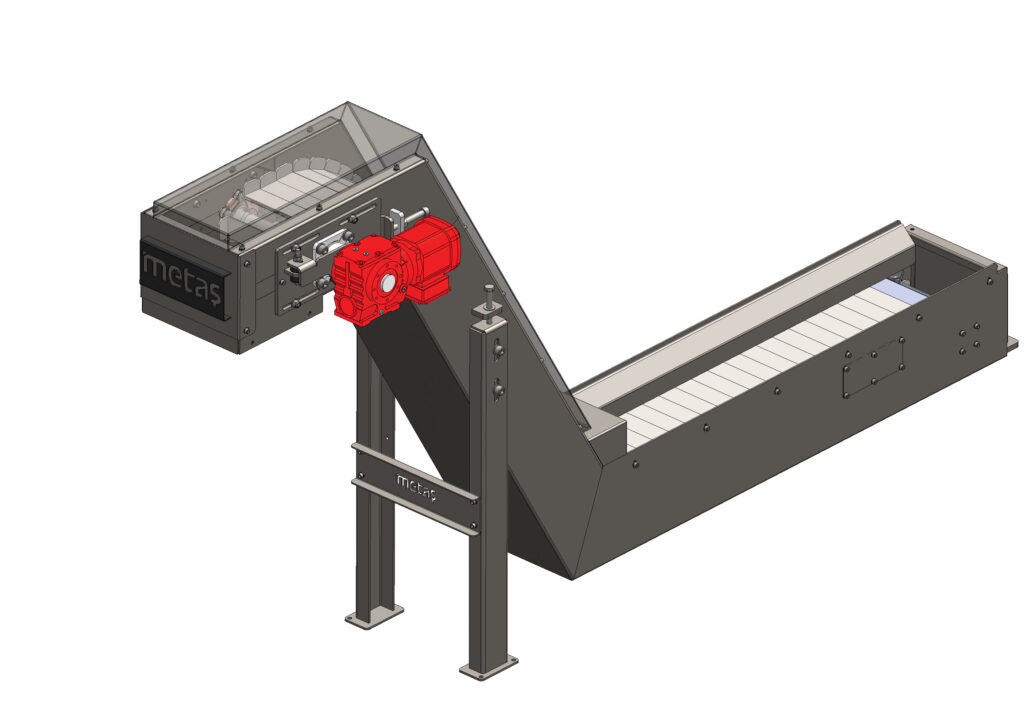

Slat-band conveyor

Conveyor systems for optimum production logistics. As an individual module or an individual system solution

To optimise your material flow and your production logistics, Metas offers individual standard conveying elements to suit the function as well as individual system solutions, ranging from system technology for bulk goods to conveyor systems for recycling operations and plants. As a result of the ongoing innovative further developments in the individual products, Metal offers all the know-how of a Full Service Provider.

Metas offers you the following high quality products designed as modules or as an individual system solution:

- Augers (screw conveyors) and dosing screws

- Scraping conveyors

- Slat-band chain conveyors

Scraper conveyor

Slat-band chain conveyor

Metas conveyor systems, the correct solution for all sectors and branches of industry

The demanding material requirements for the transportation of bulk materials are met through the use of high quality components and the high quality standard of the fabrication. The result is a capable conveyor solution, which is designed for trouble-free long-term operation, which works with minimum energy requirements and optimum resilience / reliability.

The basis for every consideration is the customer’s detailed way of looking at the problem and his conceptual formulation. The systems are tailored precisely to the customer’s requirements and the containers that are to be processed.

Conveying trials and bulk material examinations are a safeguard for how we interpret the systems. We offer our customers the following possibilities:

- Continuous or non-continuous conveying by way of suction

- Continuous conveying by way of pressure

- Vibration chutes and pipes

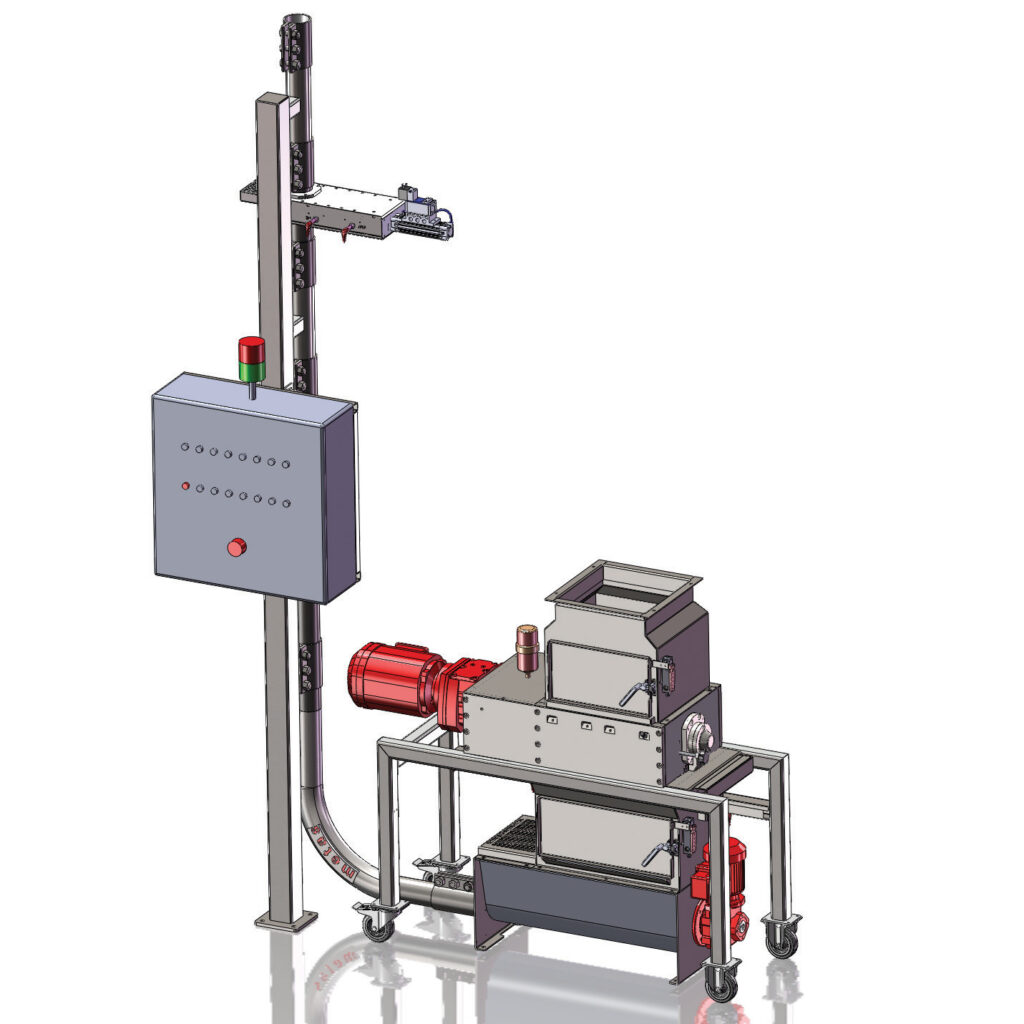

Vacuum systems

Extraction system with chip shredder and dosing screw for chip extraction

Vacuum technology is a technology, which is becoming more meaningful for applications.

Metas uses vacuum pumps, which were especially designed for industrial applications; they convey in a constant vacuum, have a high suction capacity while using completely oil-free compaction at the same time. These vacuum pumps operate without contact: No operating materials such as oil or water are required for the compaction process.

Maintenance-free

No-contact compaction prevents friction, as it develops no abrasion. No consumables have to be examined or replaced.

Economically advantageous

High-energy savings are possible because of the high degree of efficiency of the vacuum principle. There are no more downtimes and costs for consumables and operating materials as a result of the reduction in maintenance work.

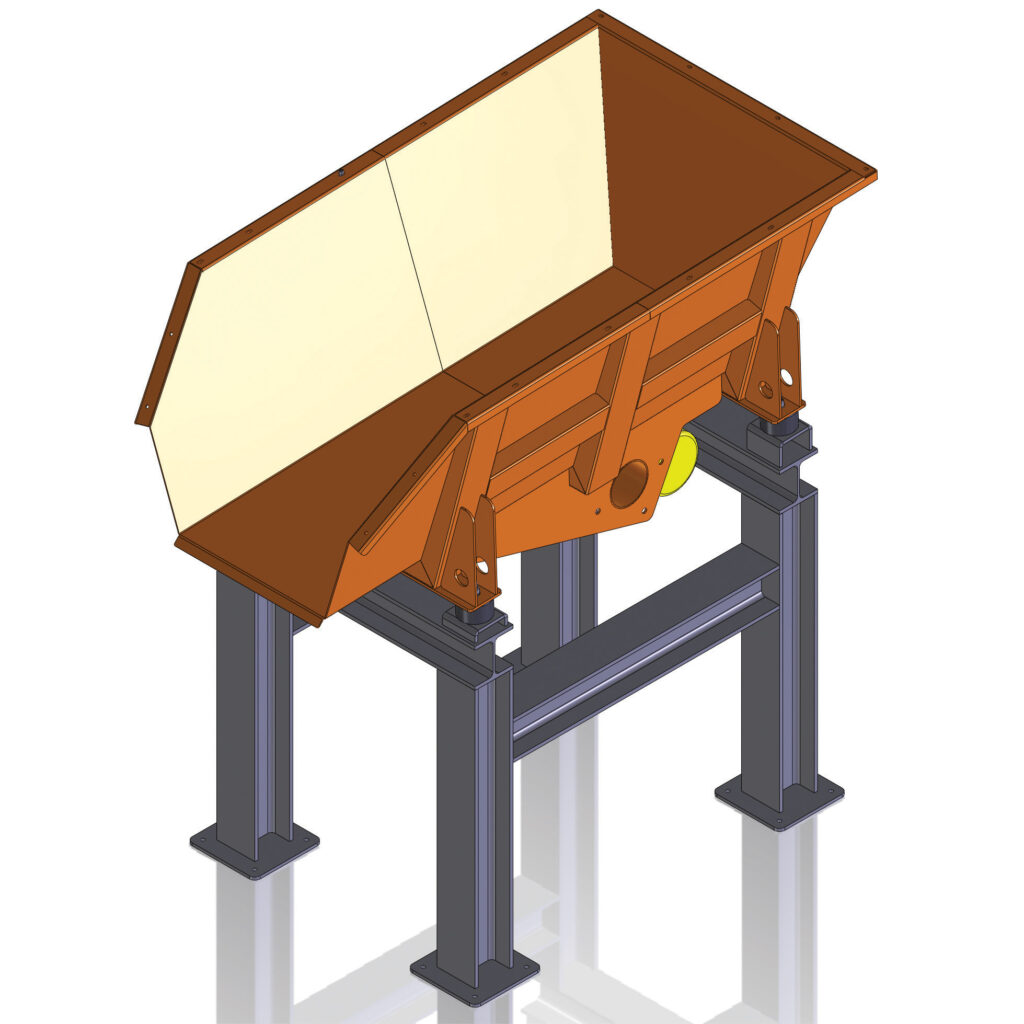

Vibrating chutes

Vibration trough – design as vibration conveyor trough in welded steel construction

We manufacture vibrating chutes of various sizes and styles.

We can offer you a custom solution for various intended uses.

Our vibrating chutes are intended for loading systems and hand-picking belts, de-watering and sieving during the conveying process.

Vibrating chutes:

· Conveying troughs

· Distributing channels (Distributaries)

· Drainage channels

· Sieving troughs

You can profit from our international know-how because Metas is familiar with the requirements for modern conveyor systems and offers optimum, scaleable concepts. Talk to us without any obligation on your behalf.